The Brief

When a specialist supplier to the forestry propagation industry sought a UK-based partner to reduce their carbon footprint and build strong supply chain relationships, BSA Mouldings emerged as the ideal choice. The client faced the challenge of producing a technically complex product, requiring a supplier with precision and expertise.

The Challenge

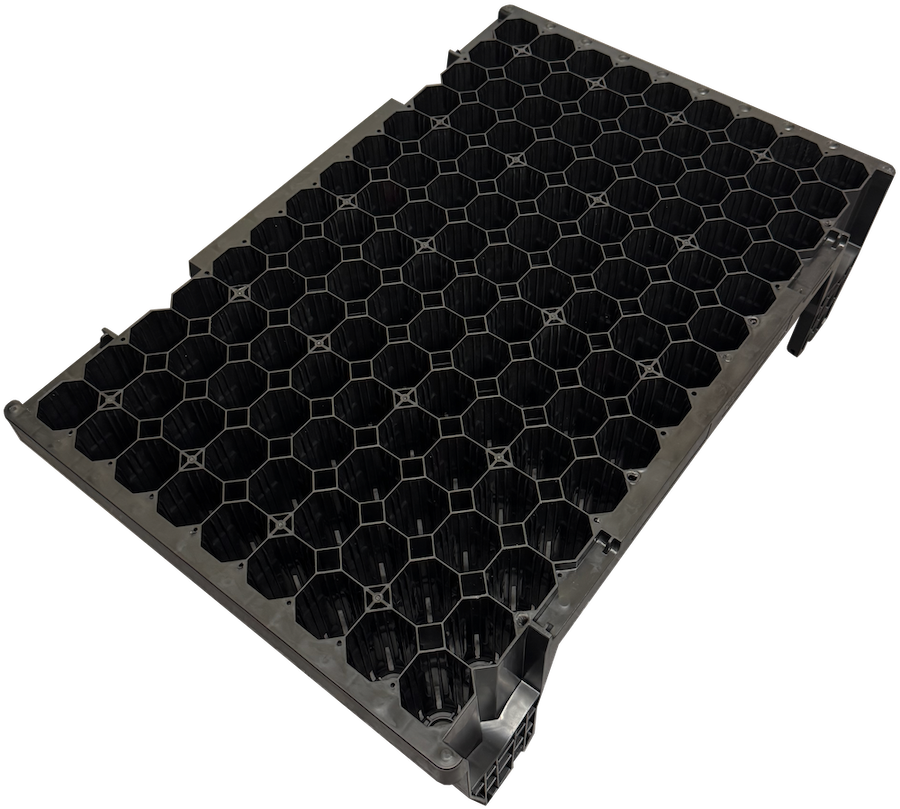

Technical Complexity: The forestry propagation trays had numerous gates in a confined space, demanding high accuracy machine processing.

Concept to Reality: The client needed a partner to transform their complex designs into market-ready products.

Supply Chain Support: Ensuring efficient supply chain management and on-time supply was crucial.

The Solution

Collaborative Design: BSA worked closely with the client, using 3D printed prototypes to validate and refine the concept designs, using technology created by Proptek.

Precision Manufacturing: Leveraging their expertise, BSA ensured the trays met the high technical standards required.

Supply Chain Management: BSA provided comprehensive stocking and storage solutions, supporting the client’s supply chain needs.

The Results

Through BSA Mouldings’ expertise, the client successfully transformed their initial tray concept into four distinct models. Over the past years, BSA has produced over 300.000 trays. Beyond manufacturing, BSA continues to support the client’s supply chain, ensuring timely delivery and efficiency.