The Brief

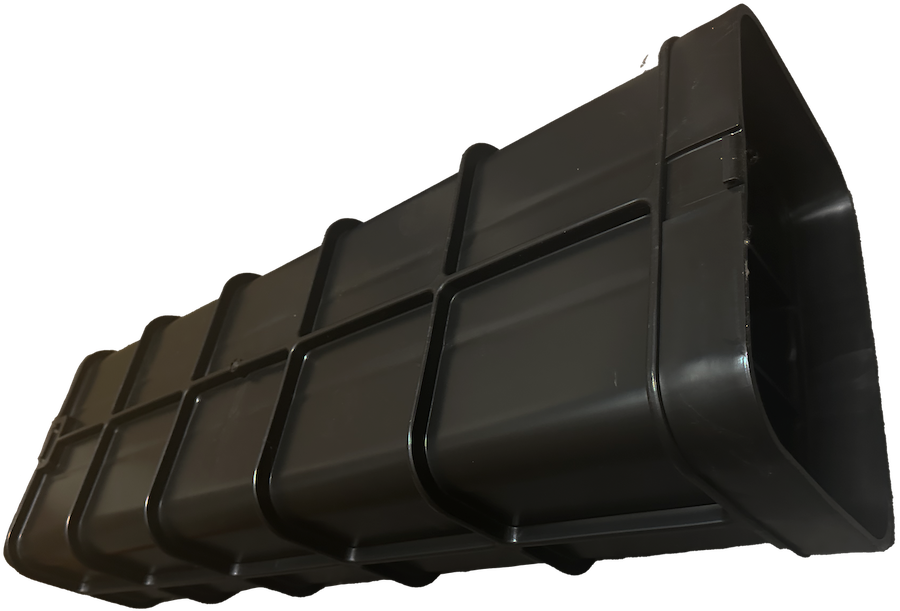

When our client developed the GENUS MEGAduct, an innovative duct bank for burying data cables in data centres and the rail industry, they faced the challenge of fulfilling a large order from Nationwide Rail under tight deadlines. They needed a UK supplier to meet carbon footprint targets and deliver high-specification, high volume products on time. Having previously collaborated with BSA Mouldings, the client knew they could rely on us for responsiveness and precision.

The Challenge

Carbon Footprint Reduction: The client sought a UK supplier that could handle recycled material to meet environmental targets.

Moulding Capabilities: Required large-scale injection moulding equipment to handle both size and volume of order, with each part being 1 metre in length and requiring 10kg shot weight of polypropylene.

Urgent Fulfilment: A large order from Nationwide Rail required prompt and precise delivery.

Dimension Accuracy: The interconnecting parts of the duct bank demanded critical dimension accuracy for a continuous fit.

The Solution

Sustainable Materials: BSA utilised 100% recyclable polypropylene, aligning with the client’s carbon footprint goals.

Moulding Capabilities: Each 1-metre part, requiring a 10kg shot weight, was moulded on a 1300-tonne machine.

Precision Manufacturing with Quality Assurance: BSA developed a jig to ensure parts were produced within precise tolerance. Rigorous QA processes ensured the parts met the required standards, providing confidence in the product’s quality.

Responsive Delivery: Leveraging their previous experience with the client, BSA ensured timely and reliable delivery to meet the tight deadlines.

The Results

Through BSA Mouldings’ expertise, the client successfully fulfilled their large order from Nationwide Rail. The innovative GENUS MEGAduct, made from sustainable materials, met all technical and environmental requirements. BSA’s commitment to precision and quality assurance ensured the product’s success.