WHAT IS INJECTION MOULDING ?

Injection moulding is a widely used manufacturing process that is often used to produce plastic products like chairs, toys and enclosures for electronic goods. The process allows even shapes of high-complexity to be produced extremely quickly from both thermoplastic and thermosetting polymers, making it a highly efficient and cost-effective manufacturing option. In addition to plastics, injection moulding can be used with other materials.

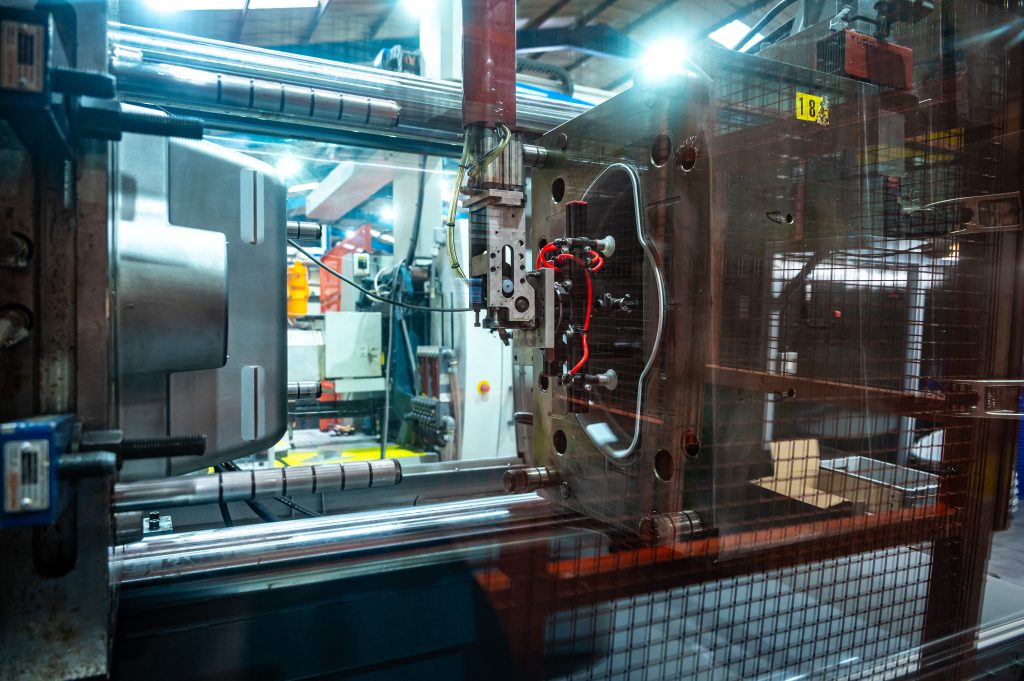

The mould inside the machine comprises of two halves, one half male and the other female. When the machine closes this enables molten plastic to inject into the mould and the cycle time also allows the moulding to cool. Inside the tool are water circuits to reduce the material temperature from about 200 degrees C to about 60 degrees C. When the mould opens the product is then ejected and a robot will then lift the moulding onto a conveyor belt.

Settings, temperatures and timings are very important factors in the process. BSA has an excellent quality control system, where production is checked every two hours.

The product can then be packed and despatched to the customer

The Plastic Injection Moulding Process comprises several stages, each integral to the production of high-quality plastic parts. Understanding these stages in detail can offer valuable insights into the complexities of this manufacturing method.

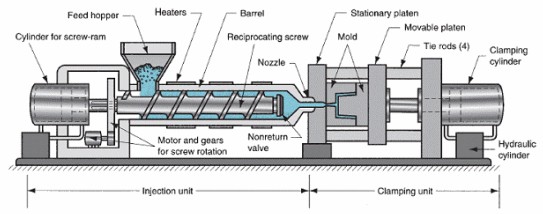

Clamping

The first stage involves securing the mould with the clamping unit. This step is crucial for maintaining the mould’s shape and integrity during the injection phase.

Injection

During this stage, the injection unit melts the plastic pellets and injects the molten plastic into the mould cavity. The speed and pressure of the injection can vary based on the type of plastic and the complexity of the part being produced.

Cooling

Once the mould is filled, the plastic begins to cool and solidify. Cooling rates must be carefully controlled to avoid defects such as warping or shrinkage.

Ejection

After the plastic has cooled sufficiently, the mould opens, and the finished part is ejected. This stage often involves additional mechanisms to ensure the part is removed without damage.

Quality Control Measures

Ensuring the quality of the final product is paramount. Various quality control measures are employed throughout the process, such as:

- Dimensional Accuracy: Employing precision measuring instruments to verify the dimensions of the moulded part.

- Material Testing: Conducting tests to ensure the plastic material meets specified standards.

- Visual Inspection: Manually inspecting the part for surface defects or inconsistencies.

Environmental Considerations

Given the growing concern for environmental sustainability, it is imperative to consider the ecological impact of plastic injection moulding. While the process itself is highly efficient, it does generate waste in the form of sprues and runners. Companies are increasingly adopting eco-friendly practices, such as recycling and using biodegradable plastics, to mitigate this impact. The Environmental Protection Agency offers guidelines on reducing the environmental footprint of plastic manufacturing.

Applications and Industries

The versatility of plastic injection moulding makes it a preferred choice for various industries. From automotive and aerospace to healthcare and consumer goods, the applications are diverse.

Cost Factors

Several factors influence the cost of plastic injection moulding, including:

| Cost Factor | Description |

|---|---|

| Mould Complexity | The intricacy of the mould design directly impacts the cost. |

| Material | The type of plastic used can significantly affect the overall expense. |

| Production Volume | Higher production volumes generally lower the cost per unit. |

WHAT IS INJECTION MOULDING ?

The method of injection moulding begins with using a raw material polymer, such as Polystyrene, Polypropylene, ABS or Nylon. There are many more polymers but these are the most common. The polymer can be coloured by adding Master Batch to match any colour desired.

The machinery varies in size from very small machines with clamp forces from 1 tonne, this would be for very small injection mouldings weighing a few grams, up to machines with a clamp force of 3000 tonnes plus, for boats and other large injection mouldings.

We are the UK’s plastic leaders in high-volume, close-tolerance injection moulding of both large and small custom plastic parts and products. We guarantee a high production output rate, low labour costs and a consistently precise tolerance.

- Simplify your operation

- Reduce your costs

- Distributed as single items, small consignments, or bulk shipments

3D Product Design

BSA offer a complete 3D design service – using our established product development processes we ensure best practice engineering techniques are incorporated into our design service

BSA Mouldings - A Partner You Can Trust

We pride ourselves on our straight-forward, honest approach and genuine care for your product. Quality-focused and committed to collaboration, our goal is to help you create a product that meets your exact specifications and expectations. Visit us to see the high standard of our factory for yourself!