Plastic Injection Moulding Services - Large Scale, HIgh volume capabIlity

As a Norfolk-based plastic injection moulding service, BSA Mouldings is your ideal partner for your plastic moulding requirements.

As one of the UK’s most reliable injection moulders, we take pride in offering competitive, innovative solutions for businesses of all sizes. Our passion resonates in everything we do, providing comprehensive services from initial product concept, compenent design, and inject mould tooling to final production.

In-mould Decoration

Traditional Finishing Techniques

When traditional finishing techniques are necessary. BSA Mouldings has the capability and expertise to carry out self-adhesive labelling, silk-screen printing, tampo printing, application of hot-foil blocking, and ultrasonic welding.

Large Scale Injection Moulding Capability

We have been using Romi-Sandretto injection moulding machines for over 20 years due to their exceptional efficiency and durability. This range of robust moulding machines enables us to serve a broad portfolio of injection moulded parts for the plastic industry.

Our diverse array of machines, scaling up to 1300 tonnes, allows us to cater to a multitude of projects/applications. Whether you require products weighing 1 gram or 10Kg, we have the capability and capacity to mould to your needs.

We mould everything from small widgets to large, complex assemblies

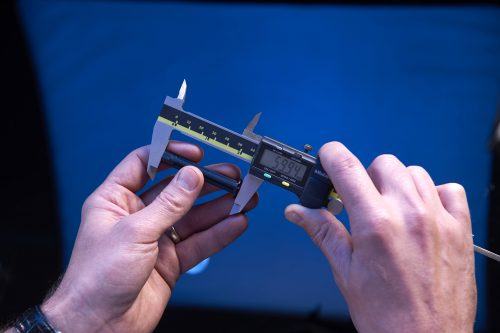

Our commitment to quality control and precision is what sets us apart as a plastic injection moulding service provider. We understand that each project has unique needs and we are adept at adjusting our processes accordingly. We employ advanced moulding technology and practices to ensure consistently high-quality output.

Material Variety and Flexibility

Our team works with a diverse range of materials, including polypropylenes, polystyrenes, ABS, acetal, polycarbonate, and long glass fibre nylon. This flexibility ensures that we can always find the perfect material for your unique application, balancing performance requirements and cost-effectiveness.

End-to-End Injection Moulding Services

At BSA Mouldings, we offer more than just moulding. We handle every step of the process, from product design and tooling to post-moulding processes such as finishing, assembly, and packaging. We believe in providing an end-to-end solution, saving you time and effort.

Choose us as your Injection Moulder

When you choose BSA Mouldings, you’re not just getting a service provider – you’re gaining a partner. We value collaborative relationships with our clients and will work closely with you to understand your needs and deliver products that exceed your expectations. Our team is dedicated, knowledgeable, and ready to assist with all of your plastic injection moulding needs. Get in touch with us today to learn more about our services and how we can help you.

Advanced plastic Moulding Technology

Harnessing the power of cutting-edge Romi-Sandretto injection moulding machines, we assure precision and quality in every part we produce. With our extensive technology-driven capabilities, we can accommodate a wide array of projects, ensuring that every moulded part adheres to the highest standards of quality and reliability.

Moulding Process Expertise

Our team possesses deep expertise in the injection moulding process, from understanding optimal material flow to fine-tuning machine parameters for maximum efficiency and quality. We ensure that every phase of the moulding process, from injection to cooling and ejection, is carefully managed for consistent results.

Custom Injection Moulding Solutions

At BSA Mouldings, we recognise that each customer has unique needs. Our team is skilled in creating custom injection moulding solutions that cater specifically to your project requirements. We work closely with you to understand your objectives, design constraints, and material preferences to deliver a customised solution that aligns with your expectations.

Cost-Effective product Production

We are committed to offering cost-effective solutions without compromising on quality. Our efficient production processes, coupled with our ability to mould parts of varying sizes and complexities, allow us to provide high-quality products at competitive prices.

After-Sales Support

Our commitment to our customers doesn’t end after production. We provide comprehensive after-sales support, ensuring that any queries or concerns you may have are addressed promptly. We’re here to assist you every step of the way, from concept to production and beyond.

Commitment to Sustainability

We understand the importance of sustainability in today’s world. That’s why we take measures to minimise our environmental impact. We continually look for ways to improve our processes and materials to be more environmentally friendly while still meeting our high-quality standards.

- Manual assembly of components

- Packing

- Ultrasonic welding, hotplate welding and Heat Stacking

- Simplify your operation

- Reduce your costs

- Distributed as single items, small consignments, or bulk shipments

BSA Mouldings - A Partner You Can Trust

Discover how our plastic injection moulding services can help bring your project to life. Contact us today to discuss your needs and learn more about how we can provide a solution tailored to your specifications. We look forward to partnering with you and delivering high-quality, reliable moulded parts that meet your exact requirements