Sandretto – Romi Machines

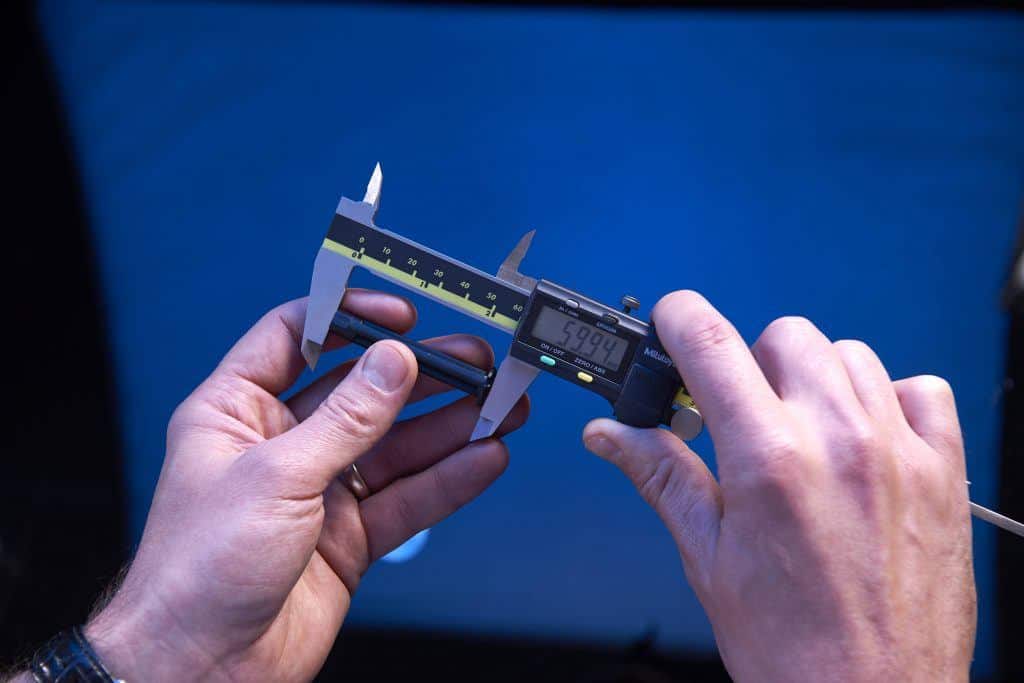

The very best machines produce the best results

BSA Mouldings have used Romi/Sandretto machines for nearly 25yrs. The main reason we use Romi/Sandretto injection moulding machines is because they are good workhorses which enable us to cover a wide portfolio of injection moulded parts for the plastics industry. We have a wide range of machines from 22 tonnes to 1300 tonnes we can cater for any number of projects/applications that our customers require, from products that weigh 1 gram to 10Kg. Romi/Sandretto’s portfolio of machinery covers all sectors of the plastics industry including Tool Making and injection moulding. Their machines are equipped with cutting-edge technology like servo-hydraulics, full-electric machine control, touch screen operations and remote diagnostics. The latest generation of machine control is equipped with a 10 or 15-inch touch screen operator panel and an economic I/O system. Due to their knowledge they fully understand our requirements. Romi have just launched the new range of Injection Moulding Machine Romi/Sandretto EN, designed with state-of-art technology, the new Romi/Sandretto EN is equipped with pumps driven by inverter-controlled motors to provide energy efficiency with excellent performance, providing savings of up to 40%. Romi/Sandretto EN will fill the needs of those who are looking for a highly efficient machine, compact, low noise level, easy to operate and simple to maintain. BSA Mouldings is proud to use Romi/Sandretto because of the level of service, technical expertise and the best possible development both in terms of quality, cost and speed of response.- Manual assembly of components

- Packing

- Ultrasonic welding, hotplate welding and Heat Stacking

- Simplify your operation

- Reduce your costs

- Distributed as single items, small consignments, or bulk shipments